According to the Federal Environment Agency, 44% of packaging was made of paper, cardboard or paperboard in 2019. The trend is rising, as plastic is increasingly being dispensed with in product packaging and trays. The basic material mostly used is virgin fibers from wood (cellulose) or recycled fibers from waste paper recycling. In the search for alternatives to the slowly renewable raw material wood, alternative cardboard packaging was developed. These are based on grass, the composite plant silphia, seaweed or agricultural waste. Is grass cardboard a clear benefit in everyday life? Will the base material replace conventional materials in the medium term? Is green cardboard packaging more cost-effective?

The advantages and disadvantages of grass cardboard packaging at a glance

Grass cardboard is a cardboard that consists of 25-50% grass fiber and recycled fiber. From a purely technical point of view, “grass-based cartonboard” is thus unpopularly described as “recycled cartonboard with a proportion of grass fiber”. As a manufacturer of cardboard or laminated corrugated packaging, we at RHIEM have been using this grass cardboard for several years. It is a climate-friendly alternative for printed product packaging, displays or shipping cartons in the cosmetics, luxury food and consumer electronics sectors. This experience provides concrete decision-making aids for new folding cartons.

Advantages

- Sustainable recycled cardboard

- The cardboard can be considered sustainable due to the absence of virgin fiber during production.

- Recyclability

- After use, the monomaterial can be fed into the recycling process without any restrictions using standard processing methods.

- Standard material

- From the manufacturer’s point of view, the material is an established standard material on the market. It is easy to work with.

- The material is readily available in selected grammages.

- The folding box becomes unique

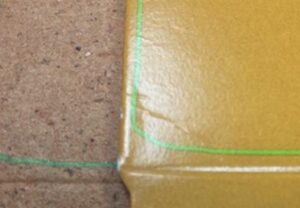

- The material has a high proportion of grass fiber, which creates a different coloration between productions.

- In addition, the position of the tangible and visible grass fibers changes. This results in a natural fluctuation between the individual packages.

Disadvantages

- Intrinsic color of the base material

- Due to the grass content, the material has a typical green-yellowish color. This means that it is not suitable for every artwork and every finish.

- In addition, the contrast between the print and the material is weaker, especially in comparison to bright white cellulose board or coated board.

- We are aware of higher fading effects in individual cases, e.g. along the creasing line.

- Structure

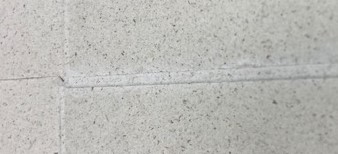

- Finer fonts or patterns are partially distorted by the structure of the material, as is the case with cardboard with agricultural waste or algae, or the font becomes more difficult to read.

- Fluctuating material coloration

- Anyone looking for a homogeneous folding box will not be satisfied with the naturally fluctuating material coloration and structure.

- Limited choice of finishes and procurement

- The material is generally not suitable for finishing with film laminates and transfer film.

- Compared to other material qualities, there are fewer manufacturers and grammages or material thicknesses.

- Pointed fibers on bending edges and tendency to edge breakage

- Some fibers protrude from the creasing lines at the edges, which is why the folding box can feel a little sharp-edged there.

- Depending on the design and processing, the edge may also crack more quickly, as is the case with conventional recycled cardboard.

Can we sustainably preserve the climate and protect the environment with packaging made from grass fibers?

In many cases, packaging is essential and it is important to optimize space first. For the subsequent assessment of the carbon footprint, the production and processing of the cardboard, the use case and, last but not least, the reusability or recycling must be considered.

What exactly is the energy balance in the production of grass-based cartonboard?

Grass cardboard currently consists of 25-50% grass fiber and recycled fiber. Recycled cartonboard is much less energy-intensive to produce than cellulose cartonboard. If you compare grass fiber with conventional wood pulp, grass fiber is often sourced from local compensation areas, whereas wood pulp was transported several thousand kilometers on average. These ecological compensation areas compensate for agricultural land use and are used for the decreasing number of livestock and paper production.

According to Creapaper, processing grass fiber saves around 300 kilograms of CO2 emissions per tonne compared to processing wood fiber, as production consumes significantly less water, energy and therefore CO2. The background to this is that the lignin contained in the wood fiber has to be removed using energy, water and chemicals.

How much packaging waste can be actively avoided with grass fiber packaging?

Grass fiber packaging can be returned to the recycling process without hesitation – at least if environmentally friendly printing and finishing processes were used during production. They therefore represent a good measure for active environmental protection. Recycled fiber can be recycled an estimated 25 times and is an ecological upgrade of pure recycled cardboard. The availability of grass cardboard is limited to some extent; – between 1.4-3.2 tons of paper can be produced from one tree(source) and grass does not offer this pulp density or is not available to us as a usable area.

What raw materials are needed in the production of grass fiber?

The cardboard consists of %-50% regional grass and waste paper.

How is grass cardboard packaging disposed of by the end user?

Grass fiber packaging can be returned to the recycling process without hesitation – at least if environmentally friendly printing and finishing processes were used during production.

Is grass cartonboard equally suitable for primary, secondary and tertiary packaging?

No, the material is not equally suitable for all areas of application and its use must be tested individually. There is no barrier for grease and moisture.

How stable is green cardboard packaging compared to paper and cardboard?

From a purely technical point of view, grass-based cartonboard has a similarly broad range of applications as recycled cartonboard.

Award-winning: Sustainable packaging in the focus of design awards or brand ambassadors on the shelf

Long gone are the days when the unloved writing pad made of environmentally friendly wood fiber smeared the fountain pen ink at school or didn’t make a nice picture during school work due to its dreadful grey coloring.

Today, environmentally friendly raw materials even win international awards because they are truly breathtaking thanks to suitable processing methods, provide excellent protection and packaging for the product and, on top of that, catch the customer’s eye on the store shelf.

We have put together two examples of really good and sustainable packaging solutions:

Red Dot Design Award Winner 2021: Kneipp natural Care & Color

Product packaging is always an optimization of different ecological, technical, aesthetic and commercial objectives. In the case of Kneipp natural care & color lip care, the focus was on comprehensive sustainability between the product, primary and secondary packaging. The packaging material of the triangular packaging consists of 25% grass fiber and was refined with an aesthetic print image. The contouring of the packaging has also integrated a cost-effective “eye-catcher”.

Red Dot Design Award: Kneipp natural care & color (red-dot.org)

Hello vegan from Lindt Germany

In the alternative luxury goods segment, this packaging solution stands for consistent communication of vegan chocolate paired with sustainable packaging. The non-profit organization Peta has once again awarded this product.

Natural grass fiber packaging at RHIEM

As a developer and manufacturer of packaging solutions for international brands, we have been focusing on environmentally friendly production processes and raw materials for many years in order to meet customer requirements, product requirements, environmental protection requirements and the recyclability of the materials used. For some time now, we have been increasingly using grass fiber packaging for customers who want to position themselves more strongly in the area of sustainability. In our view, sustainable and environmentally friendly processes and raw materials will become more important in the production of packaging in the foreseeable future. The availability and scarcity of resources are both key factors that are visibly accelerating this process.

In the further processing of the sustainable material, we rely on our own power supply, heat recovery, energy-efficient LED lights, energy-optimized compressed air generation and mineral oil-free printing inks. We would be happy to show you sustainable alternatives based on your current packaging solutions.

Yours, Ulrich Treiber