Monitoring stock levels

We regularly monitor stock levels to ensure that you have sufficient stock. This ensures that your orders are dispatched on time. This involves synchronization between your store system / ERP system and the RHIEM system. Both systems therefore have the same stock. This prevents you from selling products as “available” that are not in stock.

Integrated inventory management

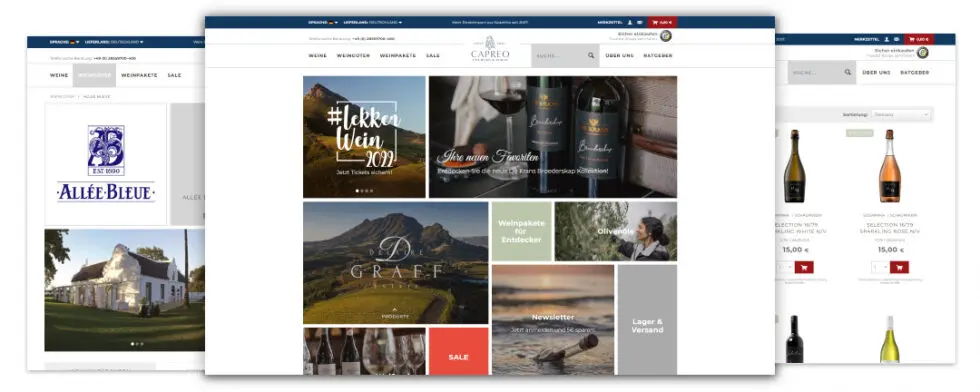

We integrate our inventory management with e-commerce systems to enable more efficient monitoring & correction. We offer interfaces to all common store and ERP systems. This saves you time and money with regard to the connection. HERE you will find an overview of currently supported systems. RHIEM itself uses Microsoft Dynamics NAV as its merchandise management system.

Monitoring sales figures

We regularly monitor daily order processing via our personal customer service. Unannounced peaks are also quickly recognized by us and we can divide capacities between customers. This makes you much more flexible in dealing with peaks than if you had your own logistics. On the IT side, we ensure synchronization between the customer system and the RHIEM system.

Cooperation with suppliers

Work closely with your suppliers to ensure that you always have sufficient stock with us. Make sure that your suppliers deliver your goods to our warehouses on time so that we can store your goods punctually and in a structured manner with the planned employees.

Stock flexibility

Make sure you are flexible enough to adapt your stock to demand. This can lead to significantly higher sales, especially in typical seasonal business (e.g. at Christmas). Incoming goods should then be announced to the logistics service provider in good time so that incoming goods are booked in on time and the goods are ready for dispatch. At RHIEM, you should allow 24-48 hours for this, depending on the size of the incoming goods.

Monitoring delivery times

We work with you to monitor and optimize your delivery times to ensure that you always have sufficient stock. RHIEM can organize the transport of your goods via sea freight, air freight and road. We work together with local experts for transportation. We can also assist with the customs clearance of the goods.

Long processing window

If orders are processed for too long, this can lead to dissatisfied customers and affect confidence in your business.

To avoid this, RHIEM does a lot to make your order processing window efficient. Here are some examples of how we can keep the processing window for your online store orders as short as possible:

Streamlining the ordering process

Together with you, we can ensure that your ordering process in the store is as simple and fast as possible to shorten the processing time. The store is of course in your hands, but we can provide IT support and integrate logics for synchronizing orders. This means that orders can be imported into the RHIEM system with a certain delay or transferred in real time. The main advantage of the former is that incorrect purchases can still be adjusted and the customer service effort on your side is reduced.

Automation of the ordering process

We fully automate the ordering process to avoid errors and save time, money and resources. RHIEM has standardized pick & pack processes for both B2C and B2B shipping. In B2C in particular, it is important to send as many parcels as possible as quickly as possible. To this end, we agree a precise packaging guideline that defines the way in which we should pack your goods. This process is then followed by our qualified shipping staff.

Monitoring delivery times

We monitor the current delivery times of our logistics partners and extrapolate logistics processes to ensure that your customers receive their orders on time. However, due to order peaks, some shipping partners are still not always able to deliver orders on time (e.g. at Christmas). If delays occur, for example on Black Friday, we work together with our shipping partners to provide a realistic estimate of when the parcels will be delivered. After all, expectation management is the key to shipping!

Communication with customers

Communicate transparently and regularly with your customers to ensure that you are always informed about the current status of their orders. We also send regular updates to your store system via the fulfillment interfaces to keep you and the end customer up-to-date at all times. This means that your customers automatically receive tracking information and no manual sending of shipping statuses is necessary.

Monitoring of orders

We monitor your orders and their status regularly and automatically to ensure that they can be processed and dispatched on time.

Monitoring stock levels

We monitor your stock levels to ensure that you always have sufficient stock to meet your customers’ needs.

We ask Andre Schwartke, Senior Manager Business Development & Sales

Supply chain management is complex. The e-commerce market offers companies of various sizes the opportunity to easily reach customers. But at the same time, competition is higher than ever – the competition is just a few clicks away on Google. In addition, B2B logistics can be used to supply retailers and distribution partners. Organizing both D2C and B2B leads to a major challenge on the retailer side – avoid the following typical mistakes at all costs:

1. shipping fluctuations in the course of the year

Just like local retail, online retail is subject to seasonal fluctuations. Christmas business begins with Black Friday – depending on the marketing, Black Week can see extreme peaks in logistics. You should prepare well for this together with the fulfillment service provider. The peaks should be discussed with the service provider months in advance so that they can schedule sufficient staff for the increase in shipments. If your business has strong peaks, it is worthwhile using an external fulfillment provider, as it is not possible to flexibly increase and decrease staff with your own logistics. A fulfillment service provider can switch personnel between customers and thus balance out peaks.

2. low investment in IT systems

You should invest in high-performance IT systems, especially after the first initial growth and the initial development of the brand. This also includes a merchandise management system so that you can coordinate both your online store and various marketplaces. The interface to the fulfillment service provider is also important here: it is essential to clarify which interfaces are supported by the company and how much development work the connection would entail. Inadequately considered costs can arise here!

3. invest in sustainability

Sustainability plays a central role for e-commerce customers. So make sure you don’t put any plastic in the parcel, use CO2-neutral shipping methods and choose a service provider that operates sustainably and generates energy using its own solar cells, for example. Customers have been aware of sustainability for a long time now, and they also base their purchasing decisions on the concept of sustainability.

Incorrect or non-existent address verification quickly leads to dissatisfied end customers because the delivery promise may not be kept.

Our address validation reduces incorrect address data and thus actively supports the end customer when placing an order.

This ensures that your customers are satisfied and that their orders are delivered quickly and efficiently.

4: Insufficient packaging

As an online store operator, it is important to ensure that all orders are properly packaged and protected to prevent damage during shipping. Inadequate packaging can lead to customers becoming dissatisfied and rating your online store negatively, which can lead to a bad reputation and potential loss of sales.

At RHIEM, we also focus on the right packaging to protect the product. On the other hand, we can also turn the packaging into a brand ambassador through our own packaging development. A unique and individual packaging design helps the end customer to identify with your product and is more likely to stand out on the shelf than the standard!

Finding the right packaging

At RHIEM, we also focus on the right packaging to protect the product. On the other hand, we can also turn the packaging into a brand ambassador through our own packaging development. A unique and individual packaging design helps the end customer to identify with your product and is more likely to stand out on the shelf than the standard!

The right packaging material

In addition, we only use high-quality packaging materials for the shipping packaging in order to pack your products safely and securely. We do not use inadequate packaging materials that could damage your products during transportation, nor do we use packaging materials that are harmful to the environment.

The right size of packaging

In addition to the right material, the right size of packaging also plays a key role. Orders are only dispatched from RHIEM if the shipping packaging is neither too small nor too large and the product cannot be damaged or move within it.

Best possible protection of the product during transportation

We also use additional protective measures such as strong adhesive tape to seal the packaging and ensure that it can provide the best possible protection for the product during transportation.

We regularly review our packaging processes to ensure that all packaging is correct and safe. We also ensure that all employees are familiar with the correct packaging processes and materials and know how to use them.

5: Incorrect shipping labeling

Incorrect shipping labeling can be a major problem for online store operators as it can lead to orders being sent to the wrong address, resulting in dissatisfied customers and potential loss of sales. Here are a few tips on how we can avoid incorrect shipping labeling along with our processes and procedures:

Careful data check

We carefully check customer information digitally to ensure that all information is correct. We dispense with any handwritten notes throughout the logistics process and instead use a printing system that ensures that all information is printed correctly and legibly – including for scanners, of course.

High degree of automation

We use an automated labeling system that can scan, print and process addresses quickly and accurately. This minimizes the chance of addressing errors being made.

We also regularly check our labeling processes to ensure that all labels are correct and legible. All employees involved in the process are continuously familiarized with and trained in these processes.

Error-intolerant address verification

By consistently using an address verification system, we can automatically check all customer addresses and ensure that they are correct and ready for delivery.

Shipping labeling is the link between the processes of the seller, the fulfillment service provider and the carrier. Only if clean and absolutely correct data is transferred to the next external process will the supply chain not be disrupted.

Deviations in the address or other important markings (e.g. the correct labeling of hazardous substances such as batteries or rechargeable batteries) can severely disrupt the supply chain or even bring it to a standstill.

Clean structures at this sensitive point are therefore essential for the rest of the process!

6: Insufficient shipment tracking

Inadequate shipment tracking can be a major problem for you as an online store operator, as it can frustrate customers if they do not receive any information about where their order is. RHIEM uses automated and intelligent communication processes throughout, which are also sent back to your store in real time thanks to the fulfillment interface.

Only reliable partners

RHIEM also uses only reliable shipping systems and partners, which also offer equally reliable and updated shipment tracking and can be linked to your connected store system via our interfaces. We work together with DHL, DPD and UPS for parcel shipping. We work with DB Schenker and various local partners for FTL shipments.

If you include your shipment tracking so prominently in your online presence that your customers can actively use it to obtain information, you offer the best possible transparency about the shipping route.

Current updates on delivery or delivery can be communicated and displayed via our interfaces.

Continuous optimization of processes

In addition, we constantly review and optimize our shipping processes in order to improve both logistical efficiency and customer satisfaction.

In our experience, active and up-to-date shipment tracking is a central part of your customer service and can actively help to ensure that customers are satisfied, recommend you to others and are just as happy to return.

Disappointment is caused by false expectations! Don’t frustrate the end customer – in many cases, they are not even aware of the many processes and procedures of the complex supply chain and the many hands through which the order is processed.

If the person placing the order loses transparency and an overview of the path of the goods, he or she may make a statement at a random, but high-profile location.

It costs many times more to win back a customer’s trust than it does to acquire a new customer.

Transparency and reliability throughout the entire delivery process is therefore of great economic importance – count on RHIEM’s experience and logistical expertise here too.

7. incorrect return processing

If returns processing is faulty, this may result in customers not being able to initiate returns or returns not being processed correctly. This results in long waiting times for the end customer, which in turn leads to greater frustration and tends to result in negative reviews of your store – often regardless of the quality of the actual product purchased.

Dealing with returns is therefore an important and central component of your customer service when it comes to end customer satisfaction. RHIEM supports you with a variety of automatic functions and up-to-date processes in our fulfillment interfaces.

In addition to these automatic processes, RHIEM actively offers assistance via our customer advisors on the correct handling of returns or appropriate compensation.

Provide a clear returns policy

A clearly formulated return procedure, which also describes the requirements for the return in simple terms, helps to simplify the return process for the end customer and at the same time noticeably reduces your service costs.

Use a simple return procedure

Make sure that all necessary information is provided centrally in the online store in such a way that a smooth return is guaranteed.

Fast returns processing

Thanks to our automated processes, we use our fulfillment interfaces to inform you as quickly as possible about the receipt and condition of your customers’ returned goods so that you can make a binding statement to the customer about the next steps in processing without losing any time.

Our state-of-the-art returns management system enables you to work quickly and reliably with your customers – even in emotionally stressful situations such as returns, warranty services or the processing of warranty claims. With RHIEM you can quickly answer customer queries, solve problems and actively contribute to greater customer satisfaction in your online store, because effective communication is an important part of your customer service.

8. technical availability of your online store

As a store operator, it is essential to ensure the technical availability of your store. The constant availability of your online store is of great importance for the success of your business, because if the server or store is temporarily down, no sales can be generated.

Even if the total failure of your store is less likely, performance problems due to undersized servers or servers with too high a load can also lead to functions, areas or interfaces of your store not working at times and customers being disappointed. Misconfigurations of the store itself can also lead to partial or total failures in everyday use.

To ensure the technical availability of your store, we offer our customers regular maintenance to identify and rectify problems before they lead to downtime. We can also provide a redundant infrastructure so that the store can continue to operate safely even in the event of a failure.

Regular monitoring tests by external services objectively ensure that your store is always available.

As a full-service fulfillment provider, RHIEM can not only operate your logistics smoothly, but also offers the necessary technical structures for successful online sales. In this way, we can ensure the success of your business and gain the trust of your customers together.